Top Quality ASTM 403 Stainless Steel Butt Weld Fittings Manufacturer, ANSI B 16.9 SS High Pressure Pipe Fittings Supplier, MSS-SP-43 SS Elbow, Stainless Steel Butt Weld Tee Stockist, Stainless Steel Reducers, SS Pipe End Cap Exporter in Mumbai, India

ASME SA 403 Stainless Steel 317L Butt weld Fittings, SS 310 Butt weld Fittings, Stainless Steel 316Ti Seamless Buttweld Fittings ASTM 403 347H Steel Butt weld Fittings Suppliers

Buttweld pipe fittings comprise of long radius elbow, concentric reducer, eccentric reducers and Tees.They are an important part of industrial piping systems to change direction, branch off or to mechanically join equipment to the system. Buttweld fittings are sold in nominal pipe sizes with specified pipe schedule. BW fitting’s dimensions and tolerances are defined as per ASME standard B16.9.

Butt Weld fittings are also called Welded Pipe fittings. These welded fittings in carbon steel and stainless steel offer many advantages compared to threaded and socketweld fittings. The later are only available up to 4-inch nominal size whereas butt weld fittings are available in sizes from ½” to 72”. Some of the benefits of Buttweld fittings are;

Stainless Steel Buttweld Fittings Specification

|

Specifications

|

ASTM A403 / ASME SA403

|

|

Size

|

1/2” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

|

|

Standards

|

ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

|

|

Thickness

|

5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75

|

|

Types

|

Seamless / Welded / Fabricated

|

|

Grade

|

ASTM A403 WP 304/ 304L/ 304H/316/ 316L/ 317/ 317L/ 321/ 310/ 347/ 904L

|

Types of Butt Weld Pipe Fittings

Welded pipe fittings in carbon steel and stainless steel are the joining components that make possible the assembly of valves, pipes and equipment onto the piping system. Welded fittings compliment pipe flanges in any piping system and allows;

Change direction of flow in a piping system

Connect or joint pipes and equipment

Provide branches, access and takeoffs for auxiliary equipment

A common example using welded pipe fitting is a pipe reduced by concentric reducer, welded to a weld neck flange and connected to an equipment. Figure below represent complete collection of butt welded pipe fitting

Butt Weld Fitting Collection

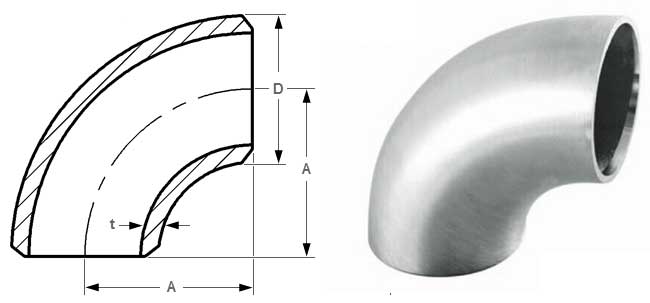

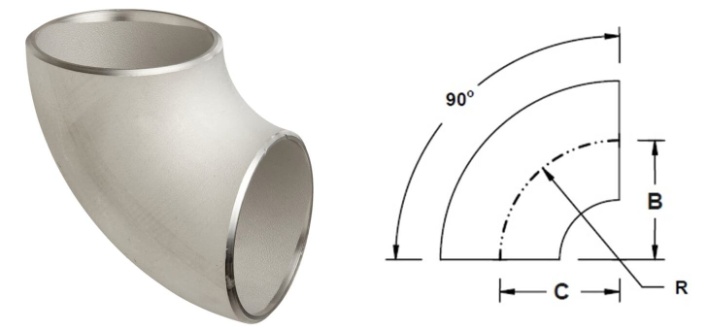

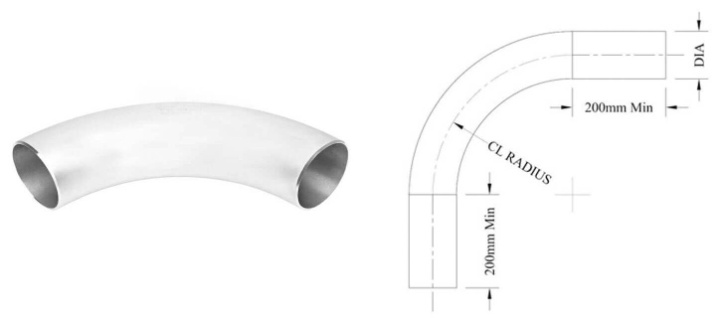

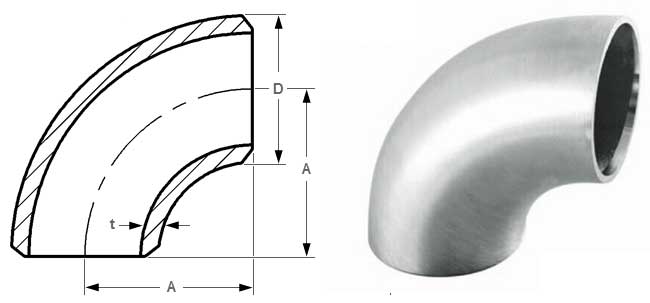

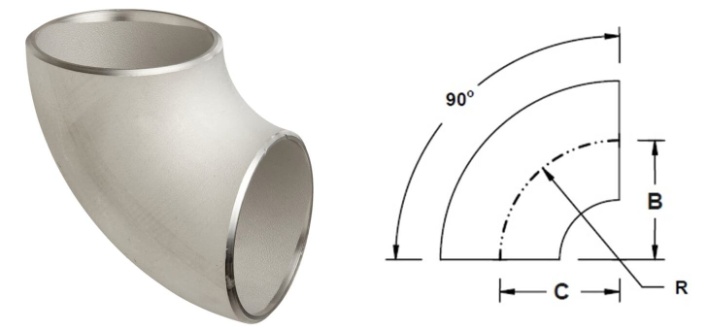

LR 90 Elbow: Fittings that change direction in a piping system are called elbows. The directional change is given in degree such as 45 or 90. Long radius 90 degree elbow has the center line of elbow at 1.5 x NPS from elbow end. 3R elbow has center line at 3 x NPS from elbow end.

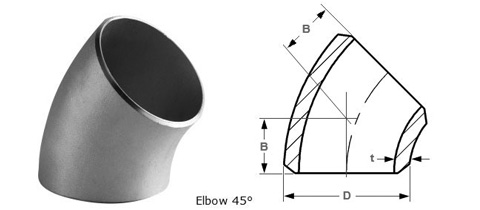

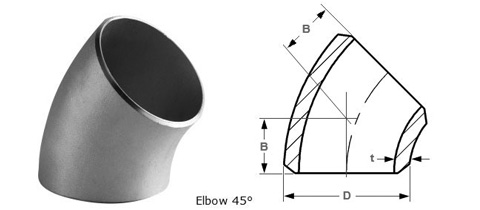

LR 45 Elbow: Long radius 45 degree elbow changes the direction by 45 degrees.

SR90 Elbow: Short Radius 90 degree elbow is the same as LR90 except for the measurement between end of elbow to center line is 1 x NPS.

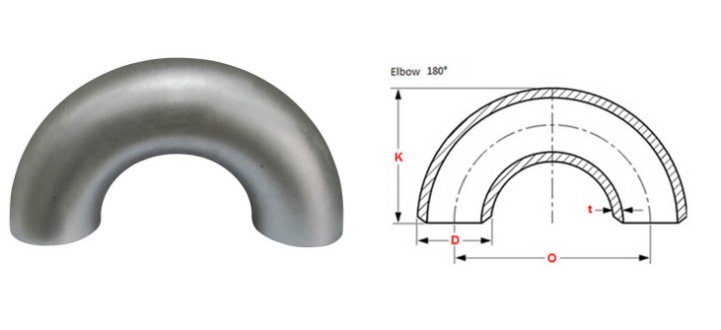

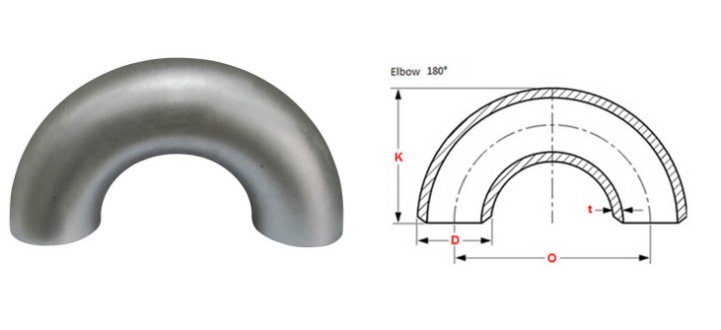

LR 180 degree Bend: Long Radius 180 degree return bend allows complete reversal of flow. The distance between end of elbow and center line is 3 x NPS.

SR 180 degree Bend: Short Radius 180 degree return bend allows complete reversal of flow but in a much tighter turn. The distance between end of elbow and center line is 1 x NPS.

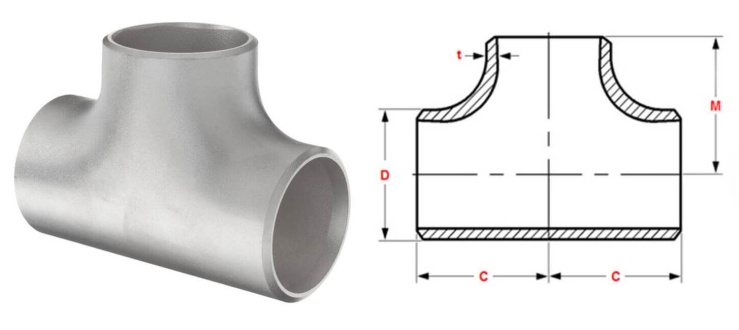

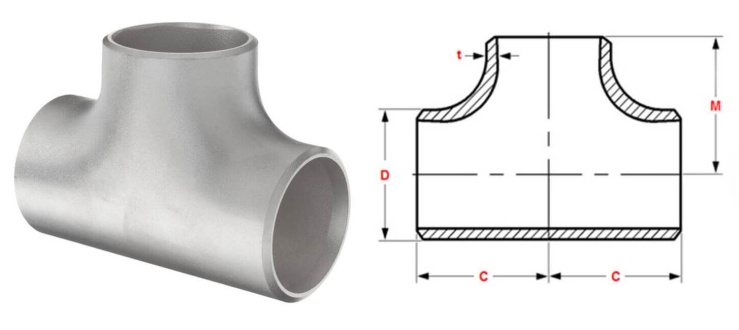

Tee: Butt weld pipe Tee allows a 90 degree branch off from a running pipe.This allows for connecting auxiliary equipment to a pipe. A tee is welded on both side to the pipe, leaving the branch open for branch off.

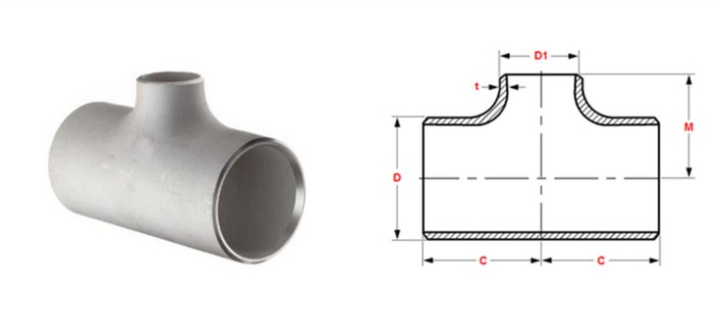

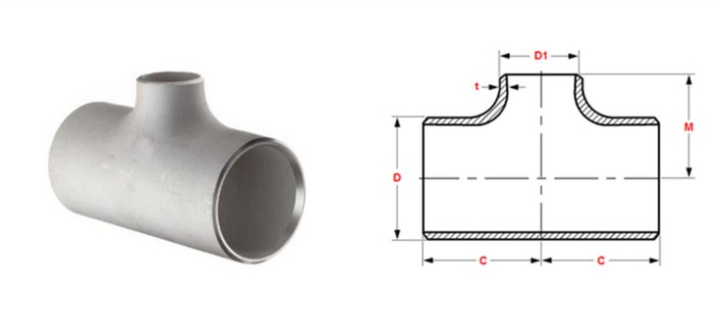

Reducing Tee: Butt weld reducing tee has a branch that is smaller than main run. This allows for branching off to a smaller pipe of equipment from the main run.

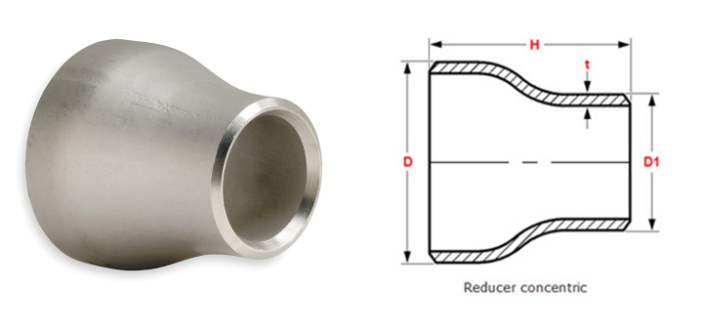

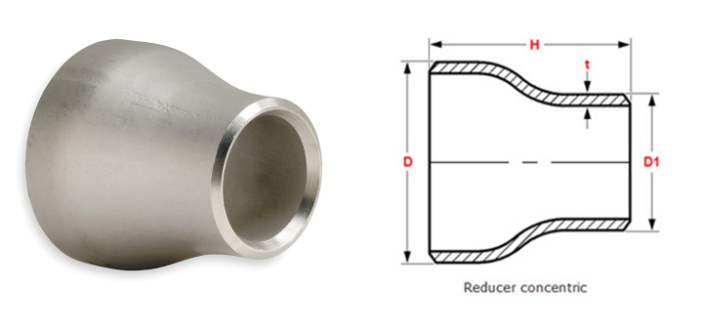

Concentric Reducer: A concentric Reducer is also called welded concentric coupling. It allows for connecting a large pipe to a smaller pipe by means of welding. A concentric reducer allows welded connection between two pipes with the same center line.

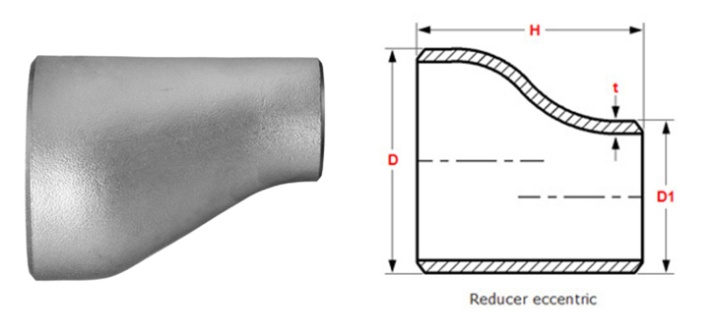

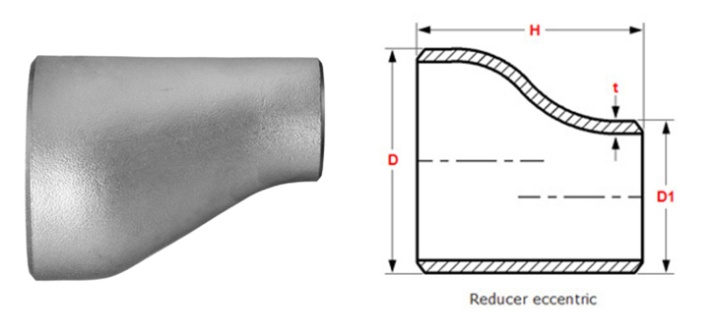

Eccentric Reducer: An eccentric reducer is also called welded eccentric coupling. It allows for welding a large pipe to a smaller pipe with an offset center line. The offset of the center line in an eccentric reducer is; Offset = 1/2 x (Largest ID - Smallest ID)

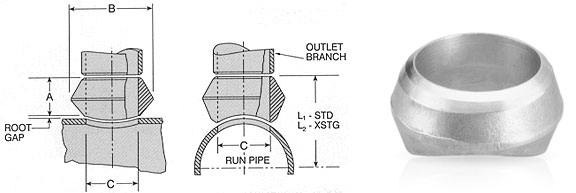

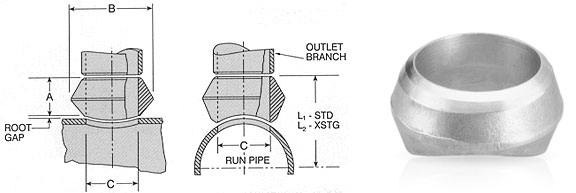

Weldolet: A weldolet, also called welding outlet, is a way of connecting a welded connection that is contoured at the bottom to match the contour of the pipe. So one end of welding outlet is welded on the pipe, whereas the other end is open to be welded to any other pipe or equipment. A welding outlet requires mentioning the size of out let and the "Run Size" of pipe so the contour can match the contour of the pipe. The size of welding outlet will always be smaller than run size such as 1/2" welding outlet can be used on pipe (run size) 1/2" and bigger.

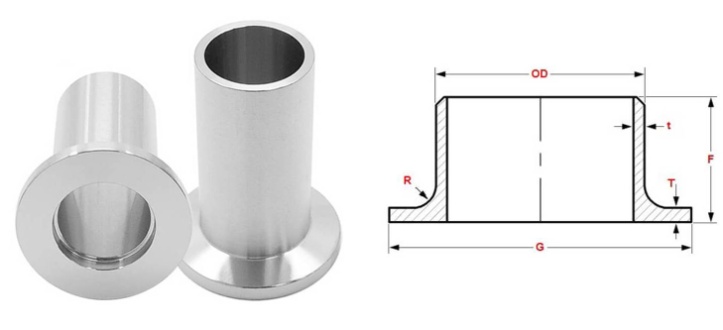

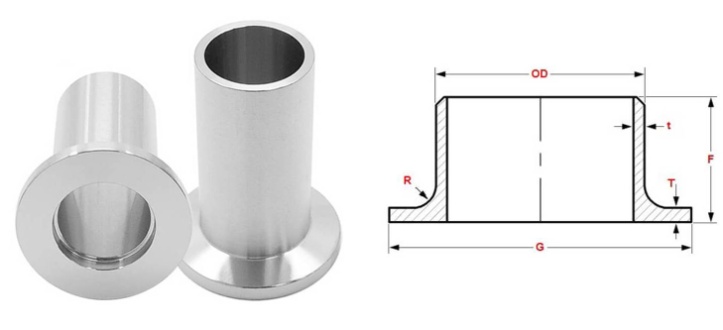

Welded Stub End: Stub ends are used with lap joint flange to be welded onto the pipe.

Butt Weld Pipe Fitting Bevel

All welded pipe fittings have bevelled ends to allow for ease of welding. This bevel allows for full penetration weld in most cases. There are two types of bevels;

Plain Bevel and Compound Bevel.

Buttweld Pipe Fitting Specification & Standards

Welded pipe fittings are made as per ASME spec B16.9. ASME B16.9 covers factory made wrought steel butwelding fittings in sizes 1/2" to 48". This standard however does not cover low pressure corrosion resistant buttwelding fittings. See MSS SP-43, Wrought Stainless Steel Butt-Welding Fittings.

Common Materials for Welded Pipe Fittings

Carbon Steel Welded Fitting:

A234 WPB is the most common material used for carbon steel butt welded fittings.

ASTM A234 WPB is the Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service.

Specifications

ASTM: A234 WPB

ASME: B16.9, B.11

NACE: MRO175

MSS: SP-83, SP-95

Chemical Composition%

|

Grade

|

C

|

Mn

|

P

|

S

|

Si

|

Cr

|

Mo

|

Ni

|

Cu

|

Others

|

|

–

|

–

|

–

|

max

|

max

|

–

|

–

|

–

|

–

|

–

|

–

|

|

WPB

|

0.3

|

0.29-1.06

|

0.05

|

0.058

|

0.1

|

0.4

|

0.15

|

0.4

|

0.4

|

V 0.08

|

|

(1,2,3,4,5)

|

max

|

–

|

–

|

–

|

min

|

max

|

max

|

max

|

max

|

max

|

Fittings made from bar or plate may have 0.35 max carbon.

Fittings made from forgings may have 0.35 max Carbon and 0.35 max Silicon with no min.

For each reduction of 0.01% below the specified Carbon maximum, an increase of 0.06% Manganese above the specified maximum will be permitted, up to a maximum of 1.35%.

The sum of Copper, Nickel, Niobium, and Molybdenum shall not exceed 1.00%.

The sum of Niobium and Molybdenum shall not exceed 0.32%.

Stainless Steel Butt Weld Fittings:

Stainless buttweld fittings are available in 316 and 304 grades.

304/304L (UNS S30400/S30403)

Chemical Composition%

|

C

|

Cr

|

Mn

|

Ni

|

P

|

S

|

Si

|

|

MAX

|

–

|

MAX

|

–

|

MAX

|

MAX

|

MAX

|

|

0.035

|

18.0- 20.0

|

2.00

|

8.0-13.0

|

0.045

|

0.030

|

1.00

|

Tensile Requirements

Tensile Strength: (KSI) = 60

Yield Strength: (KSI) = 35

(KSI converts to MPA {Megapascals} by multiplying by 6.895)

316/316L (UNS S31600/S31603)

Chemical Composition%

|

C

|

Cr

|

Mn

|

Mo

|

Ni

|

P

|

S

|

Si

|

|

MAX

|

–

|

MAX

|

|

–

|

Max

|

MAX

|

MAX

|

|

0.035

|

16.0- 18.0

|

2.00

|

2.0-3.0

|

10.0-14.0

|

0.045

|

0.030

|

1.00

|

Tensile Requirements

Tensile Strength: (KSI) = 70

Yield Strength: (KSI) = 25

(KSI converts to MPA {Megapascals} by multiplying by 6.895)

How a Butt Weld Fitting is Made?

A butt weld pipe fitting is made by the process of hot forming that includes bending and forming to shape. The starting material of butt weld fitting is a pipe that is cut to length, heated and molded into specific shapes by means of dyes. Heat treatment is also done to remove residual stresses and obtain desired mechanical properties.

Benefits of Butt Weld Pipe Fittings

Welded connection offers a more robust connection

Continuous metal structure adds to the strength of the piping system

Buttweld fittings with matching pipe schedules, offers seamless flow inside the pipe. A full penetration weld and properly fitted LR 90 Elbow, Reducer, Concentric reducer etc. offers gradual transition via welded pipe fitting.

Option of various turn radius using Short Radius (SR), Long Radius (LR) or 3R Elbows

Cost effective compared to their expensive threaded or socket weld counter parts.

Stainless Steel Welded Fittings are also available in SCH 10, allowing a more thinner wall option.

Stainless Steel Butt Weld Fittings are more common in SCH 10 and SCH 40 configuration.

All butt weld fittings have beveled ends as per ASME B16.25 standard. This helps create full penetration weld without any extra preparation needed for the butt weld fitting.

Butt weld pipe fittings are most commonly available in carbon steel, stainless steel, nickel alloy, aluminum and high yield material. High yield butt weld carbon steel pipe fittings are available in A234-WPB, A234-WPC, A420-WPL6, Y-52, Y-60, Y-65, Y-70. All WPL6 pipe fittings are annealed and are NACE MR0157 and NACE MR0103 compatible.

Mumbadevi Steel is one of the largest distributors of pipe flanges and fittings. We handle hundreds of requests every day. Some of the common misconceptions are addressed in Q&A below;

Q&A

Customer asked for butt weld fittings in A105: Most common carbon steel buttweld fitting material is A234WPB. It is equivalent to A105 flanges, however there is no such thing as A105 or A106 butt weld fitting

Customer requests “Normalized” butt weld fittings: This is also a misconception since flanges are available in A105 and A105 N, where N stands for normalized. However, there is no such thing as A234WPBN. Some manufactures normalize their butt weld fittings as a standard procedure and such request requires checking individual material test certificates to verify if normalized heat treating process was done. Customer needing “normalized” butt weld fittings should request WPL6 fittings which are high yield and are normalized as a standard procedure

Customer forgets to mention pipe schedule: Buttweld fittings are sold as per pipe size but pipe schedule must be specified to match the ID of the fitting to the ID of the pipe. If no schedule is mentioned, we will assume a standard wall is requested.

Differentiate between SCH 40 & True Schedule 40: Pipe fittings 12 inch or larger require specifying if fitting is standard wall (most commonly referred to sch 40) or a true schedule 40 is required. This is needed since schedule 40 do NOT correspond to standard wall for pipe sizes 12” and bigger. A true sch 40 will be thicker than standard wall for pipe fittings 12” or bigger.

Differentiate between SCH 80 & True Schedule 80: For pipe sizes 10 in and above, sch 80 do NOT correspond to XH. Customer must specify if they want SCH 80 or XH wall.

Stainless Steel buttweld pipe fittings are available in schedule 10s: Customer should specify if they need standard wall (sch 40s) or a thinner wall sch 10s stainless steel butt weld fitting.

Customer forgets to mention welded or seamless butt weld fitting: Butt weld fittings are available in both welded and seamless configuration. A seamless butt weld carbon steel or stainless steel fitting is made of seamless pipe and is generally more expensive. Seamless pipe fitting is NOT common in sizes bigger than 12”. Welded pipe fittings are made of ERW welded carbon steel or stainless steel pipe. They are available in sizes ½” to 72” and are more affordable than seamless fittings.

What does Short Radius (SR) or Long Radius (LR) means?

You will often hear SR45 elbow or LR45 elbow. The 45 or 90 refers to the angle of the bend for buttweld fitting to change the direction of flow. A long radius elbow (LR 90 Elbow or LR 45 elbow) will have a pipe bend that will be 1.5 times the size of the pipe. So, a 6 inch LR 90 has bending radius that is 1.5 x nominal pipe size. A short radius elbow (SR45 or SR90) has pipe bend that is equal to the size of fitting so a 6” SR 45 has bending radius that is 6” nominal pipe size.

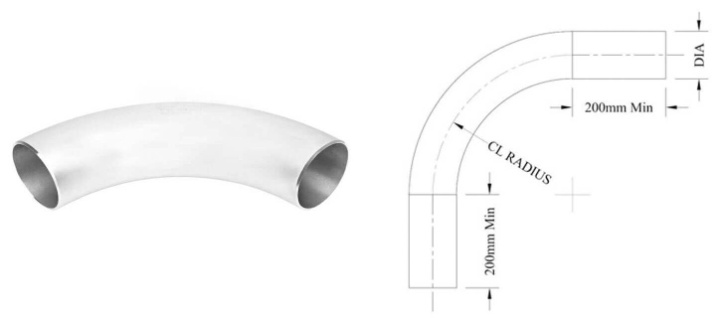

What is a 3R or 3D elbow pipe fitting?

First, the term 3R or 3D are used synonymously. A 3R butt weld elbow has bending radius that is 3 times the nominal pipe size. A 3R elbow is smoother than SR or LR fitting.

Welded Pipe Reducers

Butt weld fittings are available in concentric reducer and eccentric reducer to reduce the flow from one size of pipe to another. A concentric reducer butt weld fitting is symmetrical: both ends are aligned along the center.

An eccentric reducer butt weld fitting is not symmetrical: ends are off center of one another.

Manufacturer and Origin Options

Mumbadevi Steel India is an authorized distributor of Weldbend which is one of the largest manufacturers of domestic carbon steel butt weld fittings and flanges. Domestic stainless steel butt weld fittings are made by Mumbadevi Steel India. Mumbadevi Steel also offers approved and unapproved import pipe fittings such as Mumbadevi Steel, for more cost-conscious customers. All butt weld fittings are provided material test reports (MTR).

Types of Stainless Steel Buttweld Fittings

|

Stainless Steel 45 Degree Elbow

|

ASME SA403 SS 45 Degree Elbow

|

|

SS Buttweld Fitting

|

Stainless Steel Pipe Fitting

|

|

ASTM A403 Stainless Steel Eccentric Reducer

|

SS Concentric Reducer

|

|

Stainless Steel Equal Tee

|

ASME B16.28 Stainless Steel Lateral Tee

|

|

MSS-SP-43 Stainless Steel Short Stub End

|

Stainless Steel Long Stub End

|

|

Stainless Steel End Cap

|

SS Pipe 1D Bend

|

|

SS Pipe 5D Bend

|

SS Pipe 180D Bend

|

|

Stainless Steel U Bend

|

ANSI B16.9 WP Stainless Steel Equal Cross

|

Stainless Steel Buttweld Fittings – Grades

Mumbadevi Steels stocks a wide range of materials and grades. Below are a list of all standard stainless steel buttweld fittings materials and grades we stock.

317L Stainless Steel Buttweld Fittings

321H Stainless Steel Buttweld Fittings

347H Stainless Steel Buttweld Fittings

316Ti Stainless Steel Buttweld Fittings

310 Stainless Steel Buttweld Fittings

17.4ph Stainless Steel Buttweld Fittings

15.5ph Stainless Steel Buttweld Fittings

416 Stainless Steel Buttweld Fittings

904L Stainless Steel Buttweld Fittings

Enquire now at msi@mumbadevisteel.com or Call Us on +91 900 413 7234