Characteristics Of Carbon Steel Stub Ends:

- Have a smooth, polished surface finish.

- Seamless/welded options are available.

- Highly durable and known for precise dimensions.

- Easy and quick to assemble and dismantle as needed.

- Rust-resistant and can withstand challenging conditions.

- Suitable for multiple applications and working environments.

Call Our Experts Today!

We are one of the distinct Carbon Steel Stub Ends Exporters and Suppliers in India. Place your direct order from the website or call our executives right away. We can cater to your bulk orders.

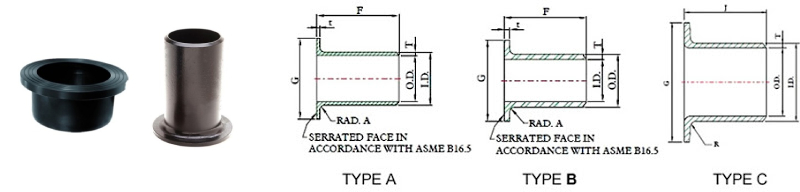

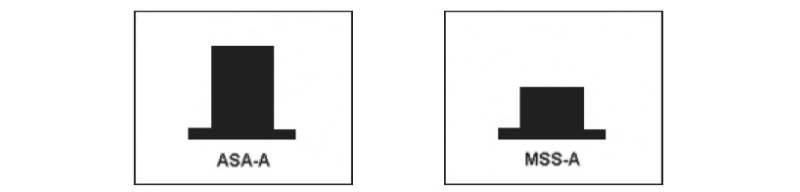

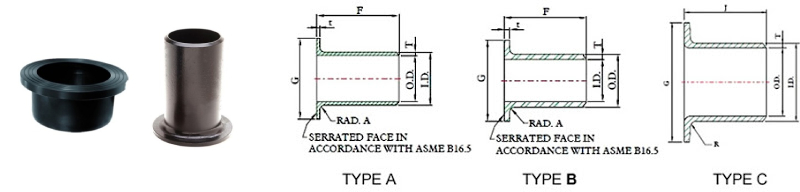

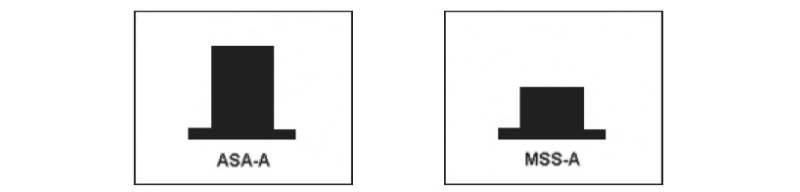

Mumbadevi Steel India manufactures custom carbon steel stub ends. We offer MSS-A (Short Pattern), MSS-C and ASA-A stub ends in all wall thicknesses including Schedules 5 and 10.

A234 WPB Mild Steel/ Carbon Steel Pipe Fittings, Flanges Manufacturer, supplier in India forged, threaded, buttweld carbon/ mild steel pipe fittings, flanges in all sizes & grades ASTM A234, ASTM A105, ASTM A420 – ASTM A106 GRADE B, ASTM A516 GRADE 60, 65, 70

Carbon Steel Stub Ends are manufactured from A106 grade B seamless pipe with Ring and Barrel Construction, per ANSI B16.9 dimensions. The ASTM Fittings Specification is WPB W, welded with no Radiograph of the weld, and they are available in sizes 2″ thru 24″ and in standard and heavy wall thickness.

Seamless stub ends are manufactured from A519/A106 hot rolled seamless to meet ASTM Fitting Specification A234WPB. ASA-A (Long Pattern) stub ends are available in size 1/2″ thru 4″ and in all wall thicknesses. MSS-A (Short Pattern) stub ends are available in sizes 1/2″ thru 6″ and in all wall thicknesses. Type B and Special length threaded stub ends are available upon request.

Material: Carbon Steel ASME / ASTM SA / A234 WPB, DIN 1.0405 / Carbon Steel: A 106 Grade B Seamless

Carbon Steel: A 519/A 106 Hot Rolled Seamless

Dimension: ANSI B16.9, ANSI B16.28, JIS B2312, JIS B2313

Thickness: Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Size: 1/2″~80″

End Prep:

Beveled Ends

Squared Ends

Flanged Ends

Grooved Ends

Threaded Ends (Male Only)

Lengths:

ASA-A Standard

MSS-A and other special lengths available

We also manufacture following grades of Carbon Steel Stub End/ Lap Joint :

- ASTM/ASME A234 WPB Stub End/ Lap Joint

- ASTM/ASME A860 Stub End/ Lap Joint

- MSS-SP-75 Stub End/ Lap Joint

- WPHY 42 Stub End/ Lap Joint

- WPHY 46 Stub End/ Lap Joint

- WPHY 52 Stub End/ Lap Joint

- WPHY 56 Stub End/ Lap Joint

- WPHY 60 Stub End/ Lap Joint

- WPHY 65 Stub End/ Lap Joint

- WPHY 70 Stub End/ Lap Joint

- Low temperature Steel Stub End/ Lap Joint

- A420 WPL3 Stub End/ Lap Joint

- A420 WPL6 Stub End/ Lap Joint

We produce following types of Carbon Steel Stub End/ Lap Joint:

- Pipe Stub End

- Lap Joint Stub End

- Short Stubend

- Long Stubend

Stockholder and distributor of an extensive range of Short Stub End, Alloy Steel Buttweld Short Stub End manufacturer

Short Stub End Dimension Chart

|

NOMINAL PIPE SIZE

|

OUTSIDE DIAMETEROF BARREL

|

LENGTH (F)

|

RADIUS (R)

|

DIAMETER (G)

|

|

MINIMUM

|

MAXIMUM

|

LONGPATTERN

|

SHORTPATTERN

|

|

1/2″

|

20.5

|

22.8

|

76

|

51

|

3

|

35

|

|

3/4″

|

25.9

|

28.1

|

76

|

51

|

3

|

43

|

|

1″

|

32.6

|

35.0

|

102

|

51

|

3

|

51

|

|

1 1/4″

|

41.4

|

43.6

|

102

|

51

|

5

|

64

|

|

1 1/2″

|

47.5

|

49.9

|

102

|

51

|

6

|

74

|

|

2″

|

59.5

|

62.4

|

152

|

64

|

8

|

92

|

|

2 1/2″

|

72.2

|

75.3

|

152

|

64

|

8

|

105

|

|

3″

|

88.1

|

91.3

|

152

|

64

|

10

|

127

|

|

3 1/2″

|

100.8

|

104.0

|

152

|

76

|

10

|

140

|

|

4″

|

113.5

|

116.7

|

152

|

76

|

11

|

157

|

|

5″

|

140.5

|

144.3

|

203

|

76

|

11

|

186

|

|

6″

|

167.5

|

171.3

|

203

|

89

|

13

|

216

|

|

8″

|

218.3

|

222.1

|

203

|

102

|

13

|

270

|

|

10″

|

272.3

|

277.2

|

254

|

127

|

13

|

324

|

|

12″

|

323.1

|

328.0

|

254

|

152

|

13

|

381

|

|

14″

|

354.8

|

359.9

|

305

|

152

|

13

|

413

|

|

16″

|

405.6

|

411.0

|

305

|

152

|

13

|

470

|

|

18″

|

456.0

|

462.0

|

305

|

152

|

13

|

533

|

|

20″

|

507.0

|

514.0

|

305

|

152

|

13

|

584

|

|

22″

|

558.0

|

565.0

|

305

|

152

|

13

|

641

|

|

24″

|

609.0

|

616.0

|

305

|

152

|

13

|

692

|

Weights of Stub End:

|

APPROXIMATES WEIGHTS

|

|

Nominal

Pipe Size

|

STUB END-ANSI LENGTH

|

STUB END-MSS LENGTH

|

|

5S

|

10S

|

40S

|

80S

|

5S

|

10S

|

40S

|

80S

|

|

1/2

|

0.059

|

0.077

|

0.145

|

0.172

|

0.047

|

0.060

|

0.077

|

–

|

|

3/4

|

0.068

|

0.086

|

0.163

|

0.231

|

0.058

|

0.073

|

0.099

|

–

|

|

1

|

0.091

|

0.141

|

0.222

|

0.395

|

0.104

|

0.172

|

0.206

|

–

|

|

11/4

|

0.132

|

0.209

|

0.318

|

0.562

|

0.130

|

0.217

|

0.276

|

–

|

|

11/2

|

0.159

|

0.250

|

0.400

|

0.685

|

0.145

|

0.242

|

0.315

|

–

|

|

2

|

0.245

|

0.377

|

0.704

|

1.406

|

0.184

|

0.308

|

0.424

|

–

|

|

21/2

|

0.350

|

0.472

|

1.071

|

2.105

|

0.303

|

0.430

|

0.731

|

–

|

|

3

|

0.468

|

0.640

|

1.489

|

2.885

|

0.342

|

0.484

|

0.870

|

–

|

|

31/2

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

4

|

0.713

|

0.981

|

2.533

|

4.250

|

0.432

|

0.641

|

1.200

|

–

|

|

5

|

1.049

|

1.239

|

3.609

|

7.575

|

0.726

|

0.878

|

1.680

|

–

|

|

6

|

1.625

|

1.952

|

5.580

|

10.433

|

0.887

|

1.080

|

2.210

|

–

|

|

8

|

2.452

|

3.110

|

10.002

|

15.831

|

1.360

|

1.940

|

3.930

|

–

|

|

10

|

4.045

|

4.871

|

13.892

|

24.313

|

2.150

|

2.530

|

5.800

|

–

|

|

12

|

6.615

|

7.123

|

19.976

|

29.348

|

2.890

|

3.250

|

7.340

|

–

|

Carbon steel pipe fittings Production Range

Carbon steel Pipe Fittings Range & Specification

|

Grade Specification

|

Carbon Steel: ASTM/ASME A234 WPB / A860 – MSS-SP-75 WPHY 42 / 46 / 52 / 56 / 60 / 65 / 70Low temperature Steel: A420 WPL3 / A420 WPL6

|

|

Type of Carbon steel Pipe Fittings

|

Seamless / Welded / Fabricated

|

|

Bending Radius

|

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

|

|

Range

|

½”NB to 48″NB in Sch 10s, 40s, 80s, 160s, XXS.

|

|

Dimensions

|

ANSI/ASME B16.9, B16.28, MSS-SP-43.

|

Buttweld Carbon steel Pipe Fittings

|

Type of Buttweld Carbon steel Pipe Fittings

|

|

Carbon steel Elbows – Long Radius

|

Carbon steel Stub Ends

|

|

Carbon steel Elbows – Short Radius

|

Carbon steel Crosses

|

|

Carbon steel Reducing Elbows

|

Carbon steel Reducing Crosses

|

|

Carbon steel 45° Elbows

|

Carbon steel 180° LR Return Bends

|

|

Carbon steel Tees

|

Carbon steel 180° SR Return Bends

|

|

Carbon steel Tees

|

Carbon steel Pipe Bends / Piggable Bends

|

|

Carbon steel Reducers

|

Carbon steel Couplings

|

|

Carbon steel Concentric Reducers

|

Carbon steel Pipe Nipples

|

|

Carbon steel Eccentric Reducers

|

Carbon steel Forged/Plate Cut Rings

|

|

Carbon steel 3D Elbow

|

Carbon steel End Caps

|

|

Carbon steel 5D Elbow

|

Carbon steel Forged / Plate Circles

|

High Pressure Forged Carbon steel Pipe Fittings

Pressure Ratings – 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

|

Type of Forged Carbon steel Pipe Fittings

|

|

Carbon steel 90° Elbows

|

Carbon steel Couplings

|

|

Carbon steel 45° Elbows

|

Carbon steel Reducers

|

|

Carbon steel Street Elbows

|

Carbon steel Inserts

|

|

Carbon steel Tees

|

Carbon steel Caps

|

|

Carbon steel Crosses

|

Carbon steel Unions

|

Carbon steel Flanges Range & Specification

|

Grade/Specification

|

ASTM A105 / A350 LF2, ASME SA105, A694 – F42, F46, F52, F60, F65, F70, A36, A516 Gr. 70, 60 etc.

|

|

Standard

|

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

|

|

Size

|

½” to 36″

|

|

Dimensions

|

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

|

|

Class / Pressure

|

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

|

|

Type of Carbon steel Flanges

|

|

Carbon steel Slip-On Flanges

|

Carbon steel Threaded Flanges

|

|

Carbon steel Weld Neck Flanges

|

Carbon steel Socket Weld Flanges

|

|

Carbon steel Blind Flanges

|

Carbon steel Reducing Flanges

|

|

Carbon steel Lap Joint Flanges

|

Carbon steel Plate Flanges

|

Carbon steel Pipe Fittings Manufacturing Standards

ASTM A182 – ASME SA182 – Standard Specification for Wrought Austenitic Carbon steel Piping Fittings

ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

ASME B16.11 – Forged Fittings, Socket – Welding and Threaded

MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

MSS SP-95 – Swage(d) Nipples and Bull Plugs

BS3799 – Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry

Carbon steel Fittings grades:

Carbon steel – ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

The material for forged Carbon steel fittings conforms to ASME A182

The dimensions for forged Carbon steel fittings conform to ASME B16.11

Carbon steel Carbon steel pipe fittings :

ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel Carbon steel pipe fittings :

Carbon Steel ASTM A105, A350 LF2, A106 Gr.B, A234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

NPT Threads conform to ASME B1.20.1

ASTM/ASME A105/SA105 The dimensions for forged carbon steel fittings conform to ASME B16.11

Alloy Steel Carbon steel pipe fittings :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

A105/A105N Forged Fittings, A182 Forged Fittings

Nickel Alloy Carbon steel pipe fittings :

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Duplex & Super Duplex Carbon steel pipe fittings :

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462

Carbon steel pipe fittings Test Certificates:

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report as per client specification.

Enquire now at msi@mumbadevisteel.com or Call Us on +91 900 413 7234