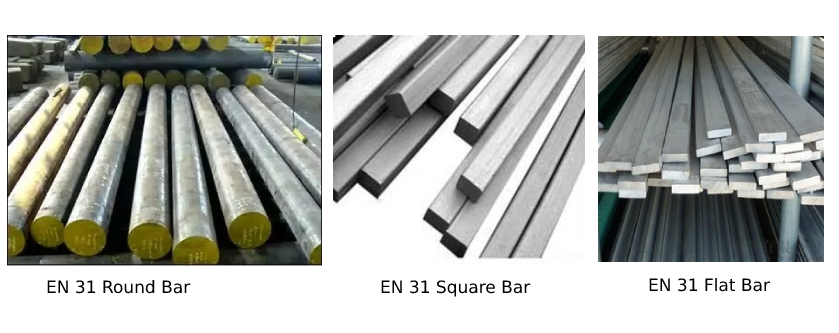

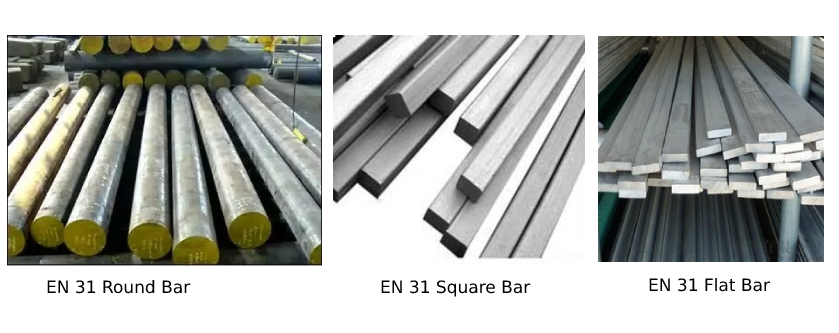

EN31 Round Bars, EN31 Flat Bars, EN 19 Square Bar, Carbon Steel Rods manufacturer, EN31 Steel Round Bar Stockiest, Supplier, Wholesaler, Distributor, Dealer, Trader

EN31 Round Bars, AISI / SAE EN31 Round Bar manufacturer, EN31 Rods Supplier, Dealer, Stockiest

We are EN31 Round Bar manufacturers and we are only manufacturing from prime quality billets and blooms. The range of EN31 Round Bars which we manufacture for our customers are of high quality and these round bars are used for making machineries and OEM Auto components. These products have been made keeping in mind the quality parameters which have been set by the industry in the market. EN31 Round Bars are always supplied with the test certificates and can be supplied in bulk quantity as well as retail quantity as per customer’s requirements. EN31 alloy Steel round bars are supplied by us to various industries.

EN31 is a very high strength steel alloy which is hardened and tempered before supplying and has nickel, chromium, molybdenum making it high tensile steel strength, with good ductility and wear resistance. With relatively good impact properties at low temperatures, EN31 is also suitable for a variety of elevated temperature applications. EN31 round bars have good internal strength and high external strength, which makes it highly wear resistant. EN31 steel round bars offer good combination of ductility, strength and wear resistance. EN31 is a very high strength alloy engineering steel.

Equivalent grades of EN31 Round Bars

BRITISH BS 970:1991 535A99

BRITISH BS 970:1955 EN31

GERMAN DIN 100CR6

FRENCH AFNOR 100C6

SWEDISH SS 2258

AMERICAN SAE 52100

CARBON STEEL EN-31 ROUND BAR SPECIFICATION

|

Grade

|

EN-31 Carbon Steel Bar

|

|

EN31 Steel Square bar size

|

4 to 100mm

|

|

EN 31 Carbon Steel Hollow Bar

|

32mm OD x 16mm ID to 250mm OD x 200mm ID)

|

|

Carbon Steel EN-31 Hex Bar size

|

2-100mm A/F

|

|

EN31 Steel Angle bar size

|

3mm*20mm*20mm~12mm*100mm*100mm

|

|

EN 31 Carbon Steel Rectangles Size

|

33 x 30mm to 295 x 1066mm

|

|

Carbon Steel EN-31 Flat bar size

|

Thickness: 2 -100mm

|

|

Width: 10 to 500mm

|

|

EN31 Steel Channel Bar

|

80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness

|

|

EN 31 Carbon Steel Section

|

3.0 to 12.0mm thickness

|

|

Carbon Steel EN-31 Round bar size

|

Diameter: 3-~800mm

|

|

EN31 Steel Billet Size

|

1/2" to 495mm Diameter

|

|

EN 31 Carbon Steel Round Bar Standard Dimensions

|

Diameter / Height:

EN31 Steel Rod and Bar Sizes : 0.5 inches / 0.625 inches / 0.75 inches / 0.875 inches / 1.0 inches / 1.125 inches / 1.25 inches / 1.375 inches / 1.5 inches / 1.75 inches / 2.0 inches / 2.25 inches / 2.5 inches / 2.75 inches / 3.0 inches / 3.25 inches / 3.5 inches / 3.75 inches / 4.0 inches / 4.25 inches / 4.5 inches / 5.0 inches / 5.25 inches / 5.5 inches / 6.0 inches / 7.0 inches / 8.0 inches / 9.0 inches.

|

|

EN31 Steel Surface

|

Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline

|

|

EN 31 Carbon Steel Tolerance

|

H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

|

|

Carbon Steel EN-31 Technique

|

EN31 Steel Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod

|

|

EN31 Steel Condition

|

Hardened & tempered, annealed

|

|

Finish

|

Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black

|

|

Form

|

EN31 Steel Round, Rod, T-Bar, EN31 Channel Bar, Precision Ground Bar, EN31 Flat Bar, EN31 Square Bar, EN31 Blocks, EN31 Round Rod, EN31 Rings, EN31 Hollow, EN31 Triangle, Rectangle, Hex (A/F), EN31 Threaded, Half Round Bar, Profiles, EN31 Billet, EN31 Ingot, I/H Bar, Forging etc.

|

|

Processing

|

Bar cutting to 650mm

|

|

Our EN31 Steel Round bar conforms to NACE MR0175/ISO 15156

|

Chemical Composition

EN31/DIN 100Cr6/AISI 52100

|

C 0.90-1.20%

|

Si 0.10-0.35%

|

MN 0.30-0.75%

|

S 0.050% max

|

P 0.050% max

|

Cr 1.00-1.60%

|

Physical Properties

|

Thermal Conductivity at °C

|

20

|

350

|

700

|

|

W/(m*K)

|

44.5

|

45.0

|

46.0

|

Application

Acceptable for many automobile applications such as heavy duty gear, shaft, pinion, camshafts, gudgeon pins. / Machining components.

Heat Treatment

|

Soft annealing °C

|

Cooling

|

Hardness HB

|

|

780-800

|

Furnace

|

max. 207

|

|

Stress-relief annealing °C

|

Cooling

|

|

600 - 650

|

Furnace

|

|

1st pre-heating °C

|

2nd and 3rd

|

Hardening °C

|

Quenching

|

Tempering °C

|

Hardness after Teperature HRC

|

|

up to approx. 400 in an air-circulating furnace

|

800 and 900

|

800-820

|

810 °C Oil ,Quench

|

at least twice 150-200

|

61 – 63

|

EN Series Chemical Compositions

|

E.N. No.

|

C

|

Mn

|

Si

|

S

|

P

|

Cr.

|

Ni

|

Mo.

|

|

EN 8

|

0.35 - 0.45

|

0.60 - 1.0

|

0.10 - 0.35

|

0.05 max

|

0.05 max

|

-

|

-

|

-

|

|

EN 8

|

0.35 - 0.45

|

0.60 - 1.0

|

0.10 - 0.35

|

0.05 max

|

0.05 max

|

-

|

-

|

-

|

|

EN 8D

|

0.40 - 0.45

|

0.7 - 0.9

|

0.05 - 0.35

|

0.06 max

|

0.06 max

|

-

|

-

|

-

|

|

EN 9

|

0.50 - 0.60

|

0.5 - 0.8

|

0.05 - 0.35

|

0.04 max

|

0.04 max

|

-

|

-

|

-

|

|

EN 15

|

0.30 - 0.40

|

1.3 - 1.7

|

0.10 - 0.35

|

0.04 max

|

0.04 max

|

-

|

-

|

-

|

|

EN 16

|

0.30 - 0.40

|

1.3 - 1.8

|

0.10 - 0.35

|

0.04

|

0.04

|

-

|

-

|

0.2 - 0.3

|

|

EN 18

|

0.35 - 0.45

|

0.6 - 0.95

|

0.10 - 0.35

|

0.04

|

0.04

|

0.85 - 1.15

|

-

|

-

|

|

EN 19

|

0.35 - 0.45

|

0.5 - 0.8

|

0.10 - 0.35

|

0.04

|

0.04

|

0.90 - 1.4

|

-

|

0.2 - 0.4

|

|

EN 24

|

0.35 - 0.45

|

0.45 - 0.7

|

0.10 - 0.35

|

0.04

|

0.04

|

0.90 - 1.4

|

1.30 - 1.8

|

0.2 - 0.4

|

|

EN 25

|

0.27 - 0.35

|

0.5 - 0.7

|

0.10 - 0.35

|

0.04

|

0.04

|

0.50 - 0.80

|

2.3 - 2.8

|

0.4 - 0.7

|

|

EN 31

|

0.90 - 1.2

|

0.3 - 0.75

|

0.10 - 0.35

|

0.04

|

0.04

|

1.0 - 1.6

|

-

|

-

|

|

EN 36B

|

0.12 - 0.18

|

0.30 - 0.60

|

0.10 - 0.35

|

0.04

|

0.04

|

0.60 - 1.1

|

3.0 - 3.75

|

|

|

EN 36C

|

0.12 - 0.18

|

0.3 - 0.6

|

0.10 - 0.35

|

0.04

|

0.04

|

0.60 - 1.1

|

3.0 - 3.75

|

0.10 - 0.25

|

|

EN 41B

|

0.35 - 0.45

|

0.6 max

|

0.10 - 0.45

|

0.04

|

0.04

|

1.5 - 1.8

|

0.40 max

|

0.10 - 0.25

|

|

EN 42

|

0.70 - 0.85

|

0.55 - 0.75

|

0.10 - 0.40

|

0.04

|

0.04

|

-

|

-

|

-

|

|

EN 45A

|

0.55 - 0.65

|

0.7 - 1.0

|

1.70 - 2.0

|

0.04

|

0.04

|

-

|

-

|

-

|

|

EN 47

|

0.45 - 0.55

|

0.5 - 0.8

|

0.50 max

|

0.04

|

0.04

|

0.8 - 1.2

|

-

|

-

|

|

EN 48A

|

0.50 - 0.60

|

0.6 - 0.9

|

1.35 - 1.65

|

0.04

|

0.04

|

0.55 - 0.85

|

-

|

-

|

|

EN 353

|

0.20 max

|

0.5 - 1.0

|

0.35 max

|

0.04

|

0.04

|

0.75 - 1.25

|

1.0 - 1.5

|

0.08 - 0.15

|

|

EN 354

|

0.20 max

|

0.5 - 1.0

|

0.35 max

|

0.04

|

0.04

|

0.75 - 1.25

|

1.5 - 2.0

|

0.1 - 0.2

|

Our Size Range Of EN31 Round Steel Bars

16mm, 18mm, 20mm, 22mm, 23.5mm, 24mm, 25mm, 26mm, 27mm, 28mm, 30mm, 32mm, 34mm, 35mm, 36mm, 37mm, 38mm, 40mm, 42mm, 45mm, 46.5mm, 47mm, 50mm, 51mm,53mm, 56mm, 60mm, 63mm, 65mm, 70mm, 75mm, 78mm, 80mm, 85mm, 90mm, 95mm, 100mm, 105mm, 110mm, 115mm, 120mm, 125mm, 130mm.

Grades We Manufacture in addition to EN31 Round Bars

MS, SAE 1018, IS 2062, A-105, SAE 1008, SAE 1010, SAE 1015, C15, C18, C20, 1020, C22, 1022, C25, 1025, C30, 1030, C35, 1035, 35C8, S35C, C40, 1040, C45, 45C8, 1045, CK45, C50, 1050, C55, 55C8, 1055, C60, 1060, C70, 41Cr4, 40Cr4, 40Cr1, En18, En18D, SAE 1541, SAE 1536, 37Mn2, 37C15, En15, SAE 1141, LF2, EN19, SAE 4140, 42CrMo4, EN24, EN353, SAE 52100, 20MnCr5, 8620, EN1A, En8, 4140D, EN9, ST 52.3, EN42, EN31, SS 410, SS 202, SS 304, SS 316 and other grades as per customer requirement.

High Carbon Anti-Friction Bearing Steel AISI 52100 Round Bar, AISI 52100 Rods, AISI 52100 Flat Bar, SAE 52100 Round Bar, SAE 52100 Rods, SAE52100 Round Bar, SAE52100 Rods, SAE52100 Flat Bar, EN31 Round Bar, EN31 Rods, EN31 Flat Bar, EN-31 Round Bar, EN-31 Rods, EN-31 Flat Bar, 100Cr6 Round Bar, 100Cr6 Rods, 100Cr6 Flat Bar, K310 Round Bar, K310 Rods, K310 Flat Bar, K-310 Round Bar, K-310 Rods, K-310 Flat Bar, Din 1.2067 Round Bar, Din 1.2067 Rods, Din 1.2067 Flat Bar, Din 1.3505 Round Bar, Din 1.3505 Rods, Din 1.3505 Flat Bar, Din 1.2327 Round Bar, Din 1.2327 Rods, Din 1.2327 Flat Bar, SUJ2 Round Bar, SUJ2 Rods, SUJ2 Flat Bar, SUJ4 Round Bar, SUJ4 Rods, SUJ4 Flat Bar, Bearing Steel Round Bar, Bearing Steel Rods, Bearing Steel Flat Bar

ASTM A322 UNS G13300 Grade AISI 1330 / SAE 1330 / SAE1330

ASTM A322 UNS G13350 Grade AISI 1335 / SAE 1335 / SAE1335

ASTM A322 UNS G13400 Grade AISI 1340 / SAE 1340 / SAE1340

ASTM A322 UNS G13450 Grade AISI 1345 / SAE 1345 / SAE1345

ASTM A322 UNS G40230 Grade AISI 4023 / SAE 4023 / SAE4023

ASTM A322 UNS G40240 Grade AISI 4024 / SAE 4024 / SAE4024

ASTM A322 UNS G40270 Grade AISI 4027 / SAE 4027 / SAE4027

ASTM A322 UNS G40280 Grade AISI 4028 / SAE 4028 / SAE4028

ASTM A322 UNS G40370 Grade AISI 4037 / SAE 4037 / SAE4037

ASTM A322 UNS G40470 Grade AISI 4047 / SAE 4047 / SAE4047

ASTM A322 UNS G41180 Grade AISI 4118 / SAE 4118 / SAE4118

ASTM A322 UNS G41200

ASTM A322 UNS G41210

ASTM A322 UNS G41300 Grade AISI 4130 / SAE 4130 / SAE4130

ASTM A322 UNS G41370 Grade AISI 4137 / SAE 4137 / SAE4137

ASTM A322 UNS G41400 Grade AISI 4140 / SAE 4140 / SAE4140

ASTM A322 UNS G41420 Grade AISI 4142 / SAE 4142 / SAE4142

ASTM A322 UNS G41450 Grade AISI 4145 / SAE 4145 / SAE4145

ASTM A322 UNS G41470 Grade AISI 4147 / SAE 4147 / SAE4147

ASTM A322 UNS G41500 Grade AISI 4150 / SAE 4150 / SAE4150

ASTM A322 UNS G41610 Grade AISI 4161 / SAE 4161 / SAE4161

ASTM A322 UNS G43200 Grade AISI 4320 / SAE 4320 / SAE4320

ASTM A322 UNS G43400 Grade AISI 4340 / SAE 4340 / SAE4340

ASTM A322 UNS G43406 Grade AISI E4340 / SAE E4340 / SAE E4340

ASTM A322 UNS G46150 Grade AISI 4615 / SAE 4615 / SAE4615

ASTM A322 UNS G46200 Grade AISI 4620 / SAE 4620 / SAE4620

ASTM A322 UNS G46210 Grade AISI 4621 / SAE 4621 / SAE4621

ASTM A322 UNS G46260 Grade AISI 4626 / SAE 4626 / SAE4626

ASTM A322 UNS G47150

ASTM A322 UNS G47200 Grade AISI 4720 / SAE 4720 / SAE4720

ASTM A322 UNS G48150 Grade AISI 4815 / SAE 4815 / SAE4815

ASTM A322 UNS G48170 Grade AISI 4817 / SAE 4817 / SAE4817

ASTM A322 UNS G48200 Grade AISI 4820 / SAE 4820 / SAE4820

ASTM A322 UNS G51170 Grade AISI 5117 / SAE 5117 / SAE5117

ASTM A322 UNS G51200 Grade AISI 5120 / SAE 5120 / SAE5120

ASTM A322 UNS G51300 Grade AISI 5130 / SAE 5130 / SAE5130

ASTM A322 UNS G51320 Grade AISI 5132 / SAE 5132 / SAE5132

ASTM A322 UNS G51350 Grade AISI 5135 / SAE 5135 / SAE5135

ASTM A322 UNS G51400 Grade AISI 5140 / SAE 5140 / SAE5140

ASTM A322 UNS G51500 Grade AISI 5150 / SAE 5150 / SAE5150

ASTM A322 UNS G51550 Grade AISI 5155 / SAE 5155 / SAE5155

ASTM A322 UNS G51600 Grade AISI 5160 / SAE 5160 / SAE5160

ASTM A322 UNS G51986 Grade AISI E51100 / SAE E51100

ASTM A322 UNS G52986 Grade AISI E51200 / SAE E52100

ASTM A322 UNS G61180 Grade AISI 6118 / SAE 6118 / SAE6118

ASTM A322 UNS G61500 Grade AISI 6150 / SAE 6150 / SAE6150

ASTM A322 UNS G86150 Grade AISI 8615 / SAE 8615 / SAE8615

ASTM A322 UNS G86170 Grade AISI 8617 / SAE 8617 / SAE8617

ASTM A322 UNS G86200 Grade AISI 8620 / SAE 8620 / SAE8620

ASTM A322 UNS G86220 Grade AISI 8622 / SAE 8622 / SAE8622

ASTM A322 UNS G86250 Grade AISI 8625 / SAE 8625 / SAE8625

ASTM A322 UNS G86270 Grade AISI 8627 / SAE 8627 / SAE8627

ASTM A322 UNS G86400 Grade AISI 8640 / SAE 8640 / SAE8640

ASTM A322 UNS G86420 Grade AISI 8642 / SAE 8642 / SAE8642

ASTM A322 UNS G86450 Grade AISI 8645 / SAE 8645 / SAE8645

ASTM A322 UNS G86550 Grade AISI 8655 / SAE 8655 / SAE8655

ASTM A322 UNS G87200 Grade AISI 8720 / SAE 8720 / SAE8720

ASTM A322 UNS G87400 Grade AISI 8740 / SAE 8740 / SAE8740

ASTM A322 UNS G88220 Grade AISI 8822 / SAE 8822 / SAE8822

ASTM A322 UNS G92590 Grade AISI 9259 / SAE 9259 / SAE9259

ASTM A322 UNS G92600 Grade AISI 9260 / SAE 9260 / SAE9260

ASTM A322 UNS G50441 Grade 50B44

ASTM A322 UNS G50461 Grade 50B46

ASTM A322 UNS G50501 Grade 50B50

ASTM A322 UNS G50601 Grade 50B60

ASTM A322 UNS G81451 Grade 81B45

ASTM A322 UNS G94171 Grade 94B17

ASTM A322 UNS G94301 Grade 94B30

Enquire now at msi@mumbadevisteel.com or Call Us on +91 900 413 7234