- Home

- Company Profile

-

Our Products

-

Stainless Steel Pipe Fittings

-

Alloy Steel Pipe

- Stainless Steel Pipe

-

Carbon Steel Seamless Pipe

-

Carbon Steel Pipe

-

Stainless Steel Tube

-

Carbon Steel ERW Pipe

-

Carbon Steel Tube

-

Alloy Steel Pipe Fittings

- Nickel & Titanium

-

Carbon Steel

- Carbon Steel (CS) Pipes, Tubes

- ASTM A106 Grade A/B Pipes, Tubes

- ASTM A53 Grade A/B Pipes, Tubes

- ASTM A333 Grade 6 Pipes, Tubes

- LSAW Steel Pipes

- API 5L B, X42 – X70 Steel Pipes, Tubes

- S355J2H, S235JRH LSAW Steel Pipe

- ASTM A252 LSAW Piling Pipe

- ASTM A234WPB Buttweld Fittings

- Carbon Steel Pipe/Tube Fittings

- ASTM A105 Carbon Steel Flanges

- ASTM A420 WPL6 Low Temp. Fittings

- Low Temperature CS Flanges

- Alloy Steels

-

Rectangular Steel Pipes, Tubes

-

Square Steel Pipes, Tubes

-

Stainless Steel Tube Fittings

-

Stainless Steel Forged Fittings

-

Carbon Steel Pipe Fittings

-

Carbon Steel Tube Fittings

-

Carbon Steel Forged Fittings

-

Stainless Steel Elbow

-

Carbon Steel Elbow

-

Stainless Steel Tee

-

Carbon Steel Tee

-

Stainless Steel Flanges

-

Carbon Steel Flanges

-

Stainless Steel Reducer

-

Carbon Steel Reducer

-

Stainless Steel Stub End

-

Carbon Steel Stub End

-

Stainless Steel Butt Weld Fittings

-

Stainless Steel Socket Weld Fittings

-

Carbon Steel Socket Weld Fittings

-

Carbon Steel Butt Weld Fittings

-

Steel Pipe Nipple

-

Stainless Steel Fasteners

-

Carbon Steel Fasteners

-

Steel Nut Bolt

-

Steel Angle

-

Steel Channel

-

Steel Beam

-

EN8 Flat Bar

-

EN19 Flat Bar

-

EN31 Flat Bar

-

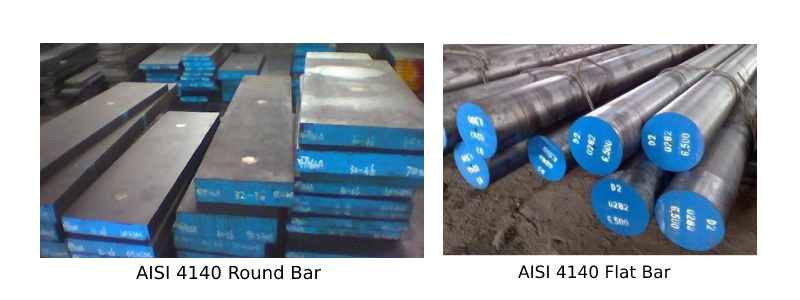

AISI 4140 Round Bar

-

D2 Round Bar

-

D3 Flat Bar

-

EN24 Flat Bar

-

Carbon Steel Plate

-

Stainless Steel Plate

-

IS 1239 Steel Pipe

-

IS 3589 Steel Pipe

-

Steel Round Bar

-

Steel Sheets

-

Galvanised Pipe

-

Galvanised Pipe Fittings

-

Steel Gate Valve

-

Ball Valve

-

Steel Needle Valve

-

Non Asbestos Sheet

-

Nylon Rods

-

UPVC Pipe

-

UPVC Pipe Fittings

-

Copper Nickel Round Bar

-

Stainless Steel

- Stainless Steel Pipes And Tubes

- Stainless Steel Rectangular Pipes

- Stainless Steel Seamless Pipes, Tubes

- Stainless Steel Welded, ERW Pipes

- SS Electropolished Pipes

- Stainless Steel Square Pipes

- Stainless Steel Capillary Tubes

- Stainless Steel Coiled Tubes

- 316, 316L Stainless Steel and Tubes

- 321/321H Stainless Steel Pipes And Tubes

- Stainless Steel 3105 Pipes And Tubes

- 347/347H Stainless Steel Pipes And Tubes

- 904L Stainless Steel Pipes And Tubes

- Duplex Pipes and Tube Manufactures

- Super Duplex Pipes and Tube Manufactures

- ASTM A312 Stainless Steel Pipes

- ASTM A213 Stainless Steel Tubes

- ASTM A249 Stainless Steel Tubes

- ASTM A269 Stainless Steel Tubing

- ASTM A270 Stainless Steel Tubing

- Polished Pipe – ASTM A554

- 310/310S Stainless Steel Pipes & Tubes

- SS 304/304L Blind Flanges

- SS 304/304L Lap Joint Flanges

- SS 304/304L Long Weld Neck Flanges

- SS 304/304L Slip On Flanges

- SS 304/304L Socket Weld Flanges

- SS 304/304L Spectacle Blind Flanges

- SS 304/304L Threaded Flanges

- SS 304/304L Weld Neck Flanges

- SS 304/304L Orifice Flanges

- SS 304/304L Plate Flanges

- SS 310/310H Blind Flanges

- SS 310/310H Lap Joint Flanges

- SS 310/310H Long Weld Neck Flanges

- SS 310/310H Orifice Flanges

- SS 310/310H Plate Flanges

- SS 310/310H Slip On Flanges

- SS 310/310H Socket Weld Flanges

- SS 310/310H Spectacle Blind Flanges

- SS 310/310H Threaded Flanges

- SS 310/310H Weld Neck Flanges

- SS 316/316L Blind Flanges

- SS 316/316L Lap Joint Flanges

- SS 316/316L Long Weld Neck Flanges

- SS 316/316L Orifice Flanges

- SS 316/316L Plate Flanges

- SS 316/316L Slip On Flanges

- SS 316/316L Socket Weld Flanges

- SS 316/316L Spectacle Blind Flanges

- SS 316/316L Threaded Flanges

- SS 316/316L Weld Neck Flanges

- SS 317/317L Blind Flanges

- SS 317/317L Lap Joint Flanges

- SS 317/317L Long Weld Neck Flanges

- SS 317/317L Orifice Flanges

- SS 317/317L Plate Flanges

- SS 317/317L Slip On Flanges

- SS 317/317L Socket Weld Flanges

- SS 317/317L Spectacle Blind Flanges

- SS 317/317L Threaded Flanges

- SS 317/317L Weld Neck Flanges

- SS 321/321H Blind Flanges

- SS 321/321H Lap Joint Flanges

- SS 321/321H Long Weld Neck Flanges

- SS 321/321H Orifice Flanges

- SS 321/321H Plate Flanges

- SS 321/321H Slip On Flanges

- SS 321/321H Socket Weld Flanges

- SS 321/321H Spectacle Blind Flanges

- SS 321/321H Threaded Flanges

- SS 321/321H Weld Neck Flanges

- SS 347/347H Blind Flanges

- SS 347/347H Lap Joint Flanges

- SS 347/347H Long Weld Neck Flanges

- SS 347/347H Orifice Flanges

- SS 347/347H Plate Flanges

- SS 347/347H Slip On Flanges

- SS 347/347H Socket Weld Flanges

- SS 347/347H Spectacle Blind Flanges

- SS 347/347H Threaded Flanges

- SS 347/347H Weld Neck Flanges

- SS 410 Blind Flanges

- SS 410 Lap Joint Flanges

- SS 410 Long Weld Neck Flanges

- SS 410 Orifice Flanges

- SS 410 Plate Flanges

- SS 410 Slip On Flanges

- SS 410 Socket Weld Flanges

- SS 410 Spectacle Blind Flanges

- SS 410 Threaded Flanges

- SS 410 Weld Neck Flanges

- SS 446 Blind Flanges

- SS 446 Lap Joint Flanges

- SS 446 Long Weld Neck Flanges

- SS 446 Orifice Flanges

- SS 446 Plate Flanges

- SS 446 Slip On Flanges

- SS 446 Socket Weld Flanges

- SS 446 Spectacle Blind Flanges

- SS 446 Threaded Flanges

- SS 446 Weld Neck Flanges

- SS 904L Blind Flanges

- SS 904L Lap Joint Flanges

- SS 904L Long Weld Neck Flanges

- SS 904L Orifice Flanges

- SS 904L Plate Flanges

- SS 904L Slip On Flanges

- SS 904L Socket Weld Flanges

- SS 904L Spectacle Blind Flanges

- SS 904L Threaded Flanges

- SS 904L Weld Neck Flanges

-

317L Stainless Steel Pipes And Tubes

-

304/304L Stainless Steel Pipes And Tubes

-

Stainless Steel Pipe Fittings

- ASTM Standards

- Clients

- Contact Us