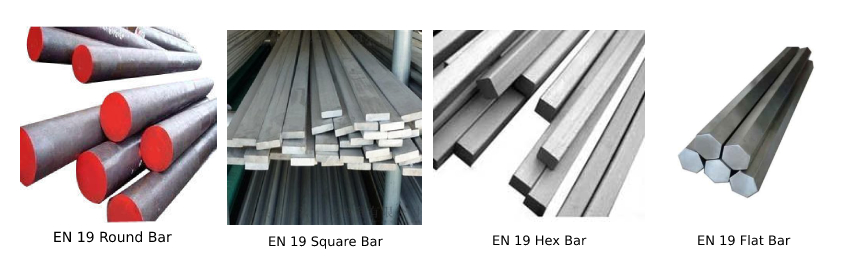

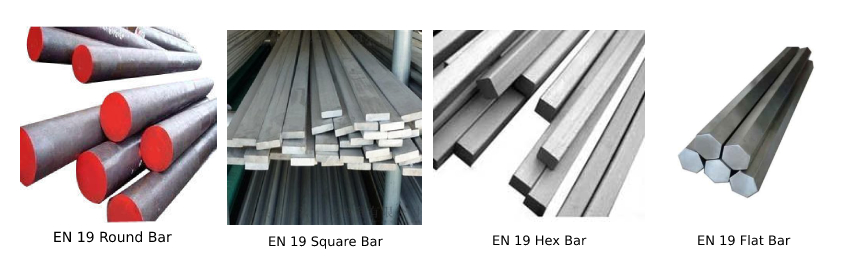

EN19 also known as 708M40 / 709M40 and AISI 4140 comes treated in the annealed as rolled or can be supplied in the T condition. We offer EN19 is a high quallity alloy steel with good tensile strength. We can supply in diameters, squares, and flats from stock. Cut to length if required.

It is renowned for its wear resistance properties and where high strength properties is required. Suitable for automotive applications such as gears, shafts, spindles, etc. If strength is a primary requirement for you application then EN19 should be considered.

|

BS 970 1991

|

BS 970 1955 EN

|

AISI/SAE

|

Werkstoff

|

|

708M40

|

EN19

|

4140

|

1.7225

|

Buy EN-19 CS Forged Bars from Carbon Steel EN-19 Hex Bar suppliers in Singapore, Canada, Houston, USA, UK, Indonesia, South Africa and Australia

Find best prices of Carbon Steel DIN 42Cr4Mo2 Bars in India. Carbon Steel EN-19 Bars manufacturer in Mumbai, India, Receive FREE AISI EN-19 sample.

Size Chart of EN 19 Round Bar

Hot Rolled EN 19 Rounds

|

Size (mm)

|

40

|

50

|

60

|

70

|

75

|

80

|

85

|

90

|

95

|

100

|

105

|

110

|

|

115

|

120

|

125

|

130

|

140

|

150

|

160

|

170

|

180

|

190

|

200

|

220

|

|

240

|

260

|

280

|

300

|

320

|

350

|

400

|

|

|

|

|

|

Bright Drawn EN19 Rounds

|

Size (inches)

|

5/16

|

3/8

|

7/16

|

1/2

|

9/16

|

5/8

|

3/4

|

7/8

|

15/16

|

1

|

1 1/8

|

1 1/4

|

1 3/8

|

1 1/2

|

|

1 5/8

|

1 3/4

|

2

|

2 1/4

|

2 1/2

|

2 3/4

|

3

|

3 1/2

|

4

|

|

|

|

|

|

|

Size (mm)

|

10

|

12

|

15

|

16

|

18

|

20

|

25

|

30

|

35

|

40

|

45

|

50

|

60

|

|

Hexagons Bright Drawn EN19

|

Size

(ins A/F)

|

0.500

|

0.600

|

0.625

|

0.750

|

0.937

|

1.010

|

1.125

|

1.300

|

1.500

|

|

|

|

|

|

Size

(mm A/F)

|

10

|

12

|

15

|

16

|

18

|

20

|

25

|

30

|

35

|

40

|

45

|

50

|

60

|

En19 Flat Bar Condition

|

H&T

|

Hardened and tempered.

|

|

ANN

|

Annealed

|

|

PH

|

Precipitation hardened.

|

Specification Chart of En19 Round Bar

|

Grade

|

EN 19

|

|

Specification

|

BS 970 1955 EN

|

|

Round bar size

|

Diameter: 3-~800mm

|

|

Hex Bar size

|

2-100mm A/F

|

|

Flat bar size

|

Thickness: 2 -100mm

|

|

Width: 10 to 500mm

|

|

Square bar size

|

4 to 100mm

|

|

Angle bar size

|

3mm*20mm*20mm~12mm*100mm*100mm

|

|

Section

|

3.0 to 12.0mm thickness

|

|

Channel Bar

|

80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness

|

|

Hollow Bar

|

32mm OD x 16mm ID to 250mm OD x 200mm ID)

|

|

Billet Size

|

1/2″ to 495mm Diameter

|

|

Rectangles Size

|

33 x 30mm to 295 x 1066mm

|

|

Finish

|

Cold (bright) drawn, centreless ground,smooth turned, peeled, slit rolled edge, hot rolled, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black

|

|

Tolerance

|

H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

|

|

Surface

|

Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline

|

|

Condition

|

Hardened & tempered, annealed

|

|

Technique

|

en19 Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod

|

|

Processing

|

Bar cutting to 650mm

|

|

Form

|

en19 Welding Rod, Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc.

|

|

Our en19 round bar conforms to NACE MR0175/ISO 15156

|

Chemical composition (EN 19)

|

C(ï¼…)

|

0.35~0.45

|

Si(ï¼…)

|

0.10~0.35

|

Mn(ï¼…)

|

0.50~0.80

|

P(ï¼…)

|

≤0.035

|

|

S(ï¼…)

|

≤0.050

|

Cr(ï¼…)

|

0.90~1.50

|

Mo(ï¼…)

|

0.20~0.40

|

|

|

Mechanical properties of steel EN19 (1.7225)

|

Nominal diameter (mm):

|

to 16

|

16 – 40

|

40 – 100

|

100 – 160

|

160 – 250

|

250 – 330

|

330 – 660

|

|

Rm – Tensile strength (MPa) (+QT)

|

1100-1300

|

1000-1200

|

900-1100

|

800-950

|

750-900

|

700

|

600

|

|

Nominal thickness (mm):

|

0.3 – 3

|

|

Rm – Tensile strength (MPa) (+A)

|

620

|

|

Rm – Tensile strength (MPa) (+AC)

|

630

|

|

Nominal thickness (mm):

|

to 8

|

8 – 20

|

20 – 50

|

50 – 80

|

|

Rm – Tensile strength (MPa) (+QT)

|

1100

|

1000

|

900

|

800

|

|

Rm – Tensile strength (MPa) (+C)

|

720

|

|

Rm – Tensile strength (MPa) (+LC)

|

670

|

|

Nominal diameter(mm): or for flat products thickness: to 8; 8-20; 20-60; 60-100; 100-160;

|

to 16

|

16 – 40

|

40 – 100

|

100 – 160

|

160 – 330

|

330 – 660

|

|

Re – Upper yield strength or

Rp0.2 – 0.2% proof strength (MPa) (+QT)

|

900

|

750

|

650

|

500-550

|

460-500

|

390

|

|

Nominal thickness(mm):

|

0.3 – 3

|

|

Rp0.2 0.2% proof strength (MPa) (+A)

|

480

|

|

KV – Impact energy (J) longitud., (+QT)

|

+20°

30-35

|

|

KV – Impact energy (J) transverse, (+QT)

|

+20°

22

|

|

Nominal thickness (mm):

|

0.3 – 3

|

|

A – Min. elongation Lo = 80 mm (%) (+A)

|

15

|

|

A – Min. elongation at fracture (%) transverse, (+QT)

|

10-14

|

|

A – Min. elongation at fracture (%) (+C)

|

4

|

|

A – Min. elongation at fracture (%) (+LC)

|

6

|

|

Nominal thickness (mm):

|

to 16

|

16 – 40

|

40 – 100

|

100 – 160

|

160 – 250

|

|

A – Min. elongation Lo = 5,65 √ So (%) (+QT), round products

|

10

|

11

|

12

|

13

|

14

|

|

Nominal diameter (mm): or for flat products thickness: to 8; 8-20; 20-60; 60-100; 100-160;

|

to 16

|

16 – 40

|

40 – 100

|

100 – 160

|

160 – 250

|

|

Z – Reduction in cross section on fracture (%) (+QT)

|

40

|

45

|

50

|

50

|

55

|

|

Z – Reduction in cross section on fracture (%) (+AC)

|

57

|

|

Brinell hardness (HBW): (+S)

|

255

|

|

Brinell hardness (HBW): (+A)

|

241

|

|

Vickers hardness ( HV): (+A)

|

195

|

|

Vickers hardness ( HV): (+QT)

|

340 – 490

|

Equivalent Grades of EN19 Round Bar

|

Standard

|

CS EN-19

|

|

UNS

|

–

|

|

WERKSTOFF NR.

|

42Cr4Mo2

|

|

BS

|

709M40

|

|

IS

|

40Cr4Mo3

|

|

JIS

|

–

|

|

EN

|

EN19

|

|

SAE/AISI

|

4140,4142

|

TYPICAL APPLICATIONS

- Commercial applications for this engineering material include:

- Automotive gears and parts

- Shafts

- Towing pins

- Load bearing tie rods

- Oil & Gas industry applications

4130 Bar, 4340 Bar, 6150 Bar, 4130 Round Bar, 4130 Heat Treated Round Bar, 4130 Rectangular Bar, 4130 Flat Bar,4130 Hex Bar,4130 Forged Bar, 4130 Square Bar, 4140 Round Bar,4140 Heat Treated Round Bar,4140 Rectangular Bar, 4140 Flat Bar,4140 Hex Bar,4140 Forged Bar, 4340 Round Bar, 4340 Norm & Temp Bar, 4340 Vac Melt Round Bar, 4340 Square Bar,4340M Rectangular Bar,4340 Flat Bar, 300M Round Bar, 300M Rectangular Bar, 300M Flat Bar, 300M Square Bar, 4340M Bar, 4340 Forged Bar, 4340 Heat Treated Round Bar,9310 Vac. Melt Round Bar, 9310 Norm & Temp Round Bar, Custom 455 Bar

Available Stock

EN19 – 709M40 Alloy Steel Bar

4340 alloy steel round bars with good price and quality

410 Alloy steel bar

2013 new craft high quality 4340 alloy steel bar

Cr12Mo1V1 DIN 1.2379 AISI D2 alloy steel bar

F11 alloy steel bar

40Cr/5140 Forged Alloy Steel Bar

High Quality Bright Alloy Steel Bar in stock

20CrMo Guide Rail/Cold drawn alloy steel bar

forged alloy steel bar

1.7225 Round Bar Steel 42CrMo4,Alloy Steel AISI 4140

Alloy Steel 4140/42crmo4 alloy steel bar

Q+T/Black or Peeled EN355 alloy steel bar

Good quality carbon and alloy steel bar S45C/4140/5140/H13/SKD11

8620 4140 42CrMo4 42CrMo alloy steel bar

stocklist of alloy steel bar

SKD61 (H13) Alloy Steel Bars Pre-hardened

34CrMo4/35CrMo/SCM435 Alloy Steel Bar

EN8 Rolled and Forged Round Alloy Steel Bar

Hot Rolled Alloy Steel Bar

alloy steel bar round bar

SACM645 Alloy Steel Bar

High precision hard chrome plated induction hardened alloy steel bar

40cr 60mm alloy steel bar round bar

4142 steel alloy steel bar

Hot rolled / forged alloy steel Bars/Plate D2 D3 4140 4340 718 H13

H13 Round Bar / H13 Alloy Steel Bar

Hot rolled/Forged(ASTM 4135/GB 35CrMo/ JISSCM435) Alloy steel bar

Factory Directly Sales SKD61 SKH51 SUJ2 D2 Alloy Steel Bar

Hot Rolled Alloy Steel Bar With Competitive price

ASTM 4135 / JIS SCM435 / DIN EN 1.7220

hot rolled alloy steel bars

40Cr Forged bar/alloy steel bar

34CrMo4 HOT ROLLED ALLOY STEEL BARS / SAG ROD

Medium Carbon Alloy Steel Bar(S45C, S55C, SUJ-2, SUS

Forged Cr12MoV alloy steel bar price per ton/kg

tool steel 56NiCrMoV7 / 1.2714 forged alloy steel bar

Forged AISI 4340/DIN 1.6511/36NiCrMo4 alloy steel bar

forging alloy steel bar 1.2312

20CrMn Hot Rolled Alloy Steel Bar

stainless hot rolled square steel bar 4340 alloy steel bar

Enquire now at msi@mumbadevisteel.com or Call Us on +91 900 413 7234